Clamp-On Laser Plates

Omega’s Clamp-on Laser Plates are used by mounting onto existing applications to provide heating or cooling of the product inside the existing vessel. Clamp-on plates are available in either single or double embosse construction, they can be flat or in the rolled orientation for use on tanks. Rather than cooling an entire room of tanks or investing in newly fabricated tanks with built-in heat exchangers, a more cost-effective solution can be

obtained by installing Omega’s Tank Clamp-on Laser Plates.

Immersion Laser Plates

Omega’s Immersion Heat Exchangers make it easy to cool or heat a numerous variety of liquids. The flexible design ensures that the plates are easy to clean and maintain. Immersion Heat Exchangers can be a single plate or an assembly of multiple Laser Plates that are banked together and immersed in a container with liquid. The medium in the plates can then cool or heat the liquid in the container. Our Immersion Products can be utilized in either a continuous flow or a batch process.

Heat Recovery Banks

Heat Recovery Banks capture heat that is exhausted or vented during plant process applications and provide energy savings by using the recovered heat in multiple preheating applications

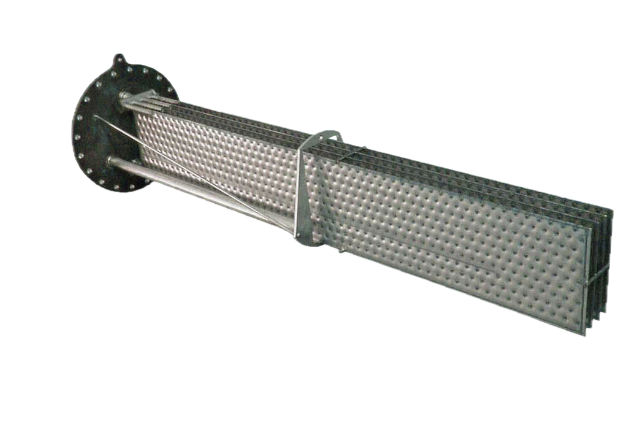

Bayonet & Suction Heaters

Bayonet heaters are an energy efficient, water saving alternative to steam sparging for heating process vessels. They are installed in the side entry of the tank. A mounting flange, which is provided, is bolted to the side of the tank for ease of insertion and removal. This allows for good natural convection circulation of the fluid being heated. These heaters are ideal for use in recirculating systems and other applications where automatically controlled temperatures are needed.

The manufacturing process for suction heaters is essentially the same as bayonet heaters with the exception of a four-sided sealed shroud that encloses the plates with an opening on the far end.