Tranter PHE, Inc. has over 65 years’ experience manufacturing gasketed and welded heat exchangers and has long been recognized as an industry leader. Tranter’s advanced plate heat exchangers span a wide product range and offer proven performance in broad applications involving liquids, gases, steam and two-phase flows. Tranter’s newly developed welded Shell & Plate Heat Exchanger is improving operations in many duties formerly handled by shell & tube and welded block-type exchangers.

NovusBloc™ - Available for global energy intensive markets the NovusBloc welded plate heat exchanger encompasses a Tranter premium design concept offering a significant boost in heat exchange performance and durability for these processes.

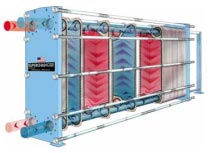

Superchanger heat exchangers are designed with a series of gasketed, embossed metal plates arranged alternately and bolted together between end frames to form channels through which hot and cold media flow to provide maximum efficiency in transferring heat from one liquid to another or from steam to liquid. Tranter offers multiple material options, and more plate flow geometries than any other manufacturer. Superchangers can handle temperature approaches of less than 2°F (1°C). They also offer “U” values in excess of 1,500 Btu/hr ft2 °F, which is significantly greater than other exchangers.

PLATECOIL® Prime Surface Heat Exchangers combine flexibility and functionality to deliver faster start-up, more efficient, economical and uniform heating and cooling to any application. Three styles of Multi-Zone and two styles of Serpentine flow configurations ensure that you get the right combination of flow rate and heat transfer rate. Where there’s a need for high internal flow rates, low pressure drop or rugged use, large-pass, heavy-gauge PLATECOIL units are available. Platecoil weighs 50-70% less than Pipe Coil and has twice the surface area in a given space. Tranter Platecoil heat exchangers can be used in many applications including eliminating sparging for reduced water and steam consumption, capturing waste energy from moist wet flue gases, recycling low-grade heat energy from drains, and improving economic performance in existing tanks and vessels with clamp-on retrofits.

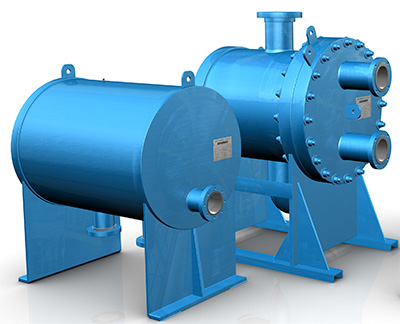

Supermax shell & plate and Maxchanger welded plate PHEs allow you to attain high heat transfer rates under elevated process conditions, in a fraction of the space and at lower cost than shell & tube exchangers. SUPERMAX and MAXCHANGER exchangers can be applied to challenging applications involving liquids, gases, steam and two-phase mixtures. This includes aggressive media, organic solvents, steam heaters and as interchangers which are beyond the capability of traditional gasketed plate & frame heat exchangers.

We can help keep your heat exchangers working trouble free. Tranter offers complete service on ALL TYPES of heat exchangers. From spare parts & gaskets to complete overhaul & redesign, Tranter offers it all.

Please contact a sales engineer to discuss Tranter heat exchangers.

Visit the Tranter website at www.tranterphe.com